Biocera coating for MAGNESIUM

Resorbability:

Biodegradable magnesium alloys as a new generation of biomedical materials have many advantages over traditional resorbable materials.

Compared with traditional polymer-based resorbables they offer better mechanical properties that align more closely with bone, and a resorption rate that allows for a gradual transition back to load-bearing bone.

This makes them ideal for applications in trauma, sports medicine, and even dental reconstruction (magnesiumdevelopment.com).

Problem:

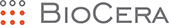

The major drawback of magnesium alloys as implants is their exceptionally high corrosion rate in the physiological environment. The high corrosion rates promote fast degradation of the mechanical properties, leading to the premature failure of implants before the normal tissue-healing process restore structural integrity. Additionally, hydrogen evolution, which is the principal cathodic reaction and concurrent with the corrosion of magnesium alloys, can significantly interfere with the healing process.

Solution:

Biocera developed dense bioceramic coatings with desirable topography and definable elemental composition to control resorption rate of magnesium alloys, provide enhanced osseointegration and antibacterial properties.

Antibacterial functionality:

ECO bioceramic surfaces have been developed by incorporating phosphate compounds and other chemical elements such as, Zn, Cu, Ga, Sr, Si, S, Ag or Zr to provide, besides osteoconduction ability and corrosion resistance the capability to inhibit and prevent microbial growth. Antibacterial surfaces on resorbable magnesium Implants address a clear clinical need to mitigate risk of late prosthetic implant infection, particularly for trauma systems associated with fractures.

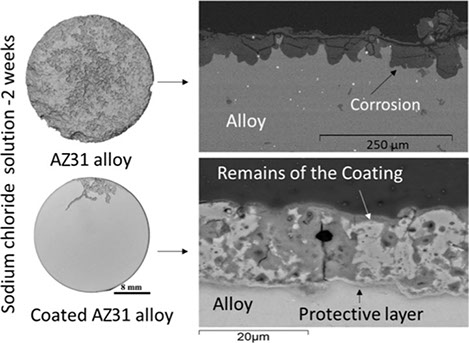

Robust, mechanically strong coating:

Polymer coatings and anodic layers on magnesium do not provide sufficient mechanical strength and adhesion to survive insertion into the bone. ECO Bioceramic layers on magnesium screws proved to maintain their integrity over multiple insertions.

a1) Full field view of the screw thread

a2) Cross-sectional view of the screw

a3,4,5) Zoom-in view of the circular cross-section

b1) Cross-sectional view of the screw after insertion and removal from the bone

b2) Zoom-in view showing the integrity and surface roughness of the cross-section