Converting metal surface into a bio-ceramic interface

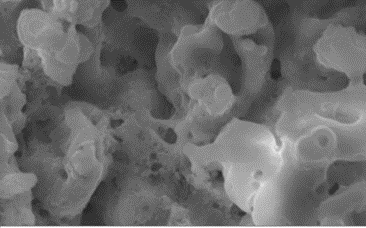

Biocera patented electrochemical oxidation (ECO) technology enables to build bioceramic layers with desired composition and topography on the surface of metal implants by combining surface oxidation with co-deposition of selected elements from electrolyte aqueous solution. During ECO process, ions present in the electrolyte get embedded with the growing oxide layer, affecting properties such as, morphology, pore size and distribution, constituent phases of the coating, wear, corrosion, biological (biocompatibility, bioactivity, osteoconduction ability, etc.) and influence microbiological interactions (adhesion, biofilm formation and proliferation).

SEM image of ECO surface: highly developed ceramic surface with micro and nano topography beneficial for osseointegration, corrosion control and antibacterial functionality.

Biocera ECO technology is environmentally friendly and does not deal with any hazardous substances. ECO process has been developed and applied for Magnesium, Titanium and Zirconium alloys.

Different electrolyte compositions and electrical coating modes enable to optimise coating performance according to specific application requirements. Such elements as calcium, phosphorous, silicium, strontium and boron proved to be efficient elements for building bioceramic material on the basis of substrate metal oxide. Elements from the list of silver, copper, zinc, gadolinium, zirconium and sulphur appeared to be instrumental for providing antibacterial properties.

Biocera coating thickness ranges from 5 to 20 microns depending on application requirements with a typical growth rate of 1-3 microns per minute.

Coating thickness greatly influences resorbability rate of Magnesium implants. Higher thickness provides higher chemical insulation and enhanced mechanical strength/scratch resistance.

Coating roughness/topography/density/porosity is controlled via parameters of electrical pulses.